So I will cronicle the progress (or lack of) here so that others may provide helpful ideas along the way. I will attempt to edit much of what will be said along the way when things dont go quite as planned (hehe).

A little about what I am looking to accomplish. I posted this in a couple other threads, but will state it again here to keep all the info in once place for anyone following my foolhardy adventure

I currently work maintaining the fleet for a travelling show. As such, I need a decent sized space for all my tools. The show has been reasonably good to me, but the 8X10 space they provided for my living area just isnt big enough, I am being overrun by tools, and those are just the ones I bought here, not the entire storage unit of tools back home.... Even should I leave the show, I will end up using the truck for residential rehabs. Flipping houses is not as sexy or as easy as they make it out on TV, but you can make a decent living at it if you know how to build a home. Especially if you dont need a motel room for weeks at a time while doing the plumbing or wiring which would make it so you cant stay in the house..

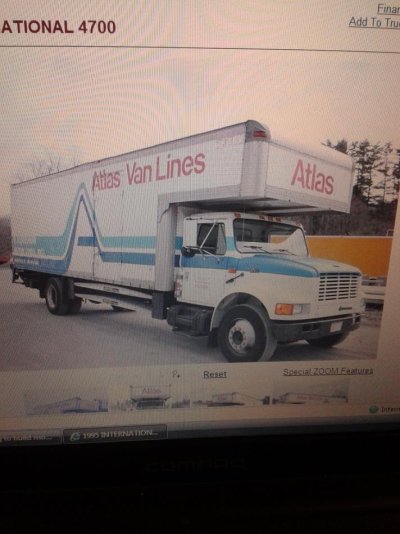

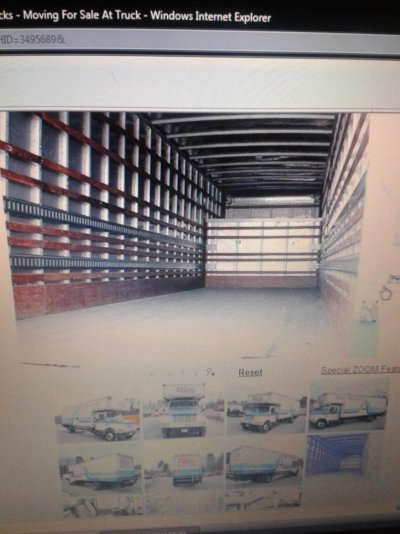

So...I decided to do a DIY conversion. This website was a huge help right out of the gate. After reading multiple threads I decided the type of truck box I was looking for. I wanted the furniture moving box for the pre-built attic area which will become the bunk. The rest of the space (the 6' attic was overkill, but it came with the truck, so I will use it) will be lightweight storage for clothing or something else very light. I dont want to overload the attic with weight.

The box itself is 25'. I will be using the last 10' of the truck for a workshop/tool storage area. (it will be a nice change of pace to not have my tools (literally) under my feet) This leaves me with little under 15' for living space, which should be enough considering the bunk is over the cab and not included in the 15'. The back of the truck has a working 1800lb liftgate, which will make loading and unloading rollaways filled with tools *much* easier

First the before pics. The truck itself is about 300 miles away from me atm, so the pics are off the net, sorry for the quality, but you will get the idea of what I am working with at least

The very first question is the decals/vinyl on the outside.. heat gun and goo gone to remove them would be my first choice. Paint will be last but I have read much on the subject so far, and I am wondering why an oil based primer but a latex/acrylic finish?

Onwards to the inside (and the important stuff). I have not seen too many pics of the insulation as it's being installed. I am guessin everyone used either straight rigid board, or lined rigid board. Where did everyone draw the line? I am thinking atm I want a R14 (or thereabouts) so I need a double layer (for a total of 2 inches). But having never done this before, I am wondering will that create chaos when it comes time to install the windows?

More as I think up an intelligent way to present the 1,000,001 questions running around in my head atm.

A little about what I am looking to accomplish. I posted this in a couple other threads, but will state it again here to keep all the info in once place for anyone following my foolhardy adventure

I currently work maintaining the fleet for a travelling show. As such, I need a decent sized space for all my tools. The show has been reasonably good to me, but the 8X10 space they provided for my living area just isnt big enough, I am being overrun by tools, and those are just the ones I bought here, not the entire storage unit of tools back home.... Even should I leave the show, I will end up using the truck for residential rehabs. Flipping houses is not as sexy or as easy as they make it out on TV, but you can make a decent living at it if you know how to build a home. Especially if you dont need a motel room for weeks at a time while doing the plumbing or wiring which would make it so you cant stay in the house..

So...I decided to do a DIY conversion. This website was a huge help right out of the gate. After reading multiple threads I decided the type of truck box I was looking for. I wanted the furniture moving box for the pre-built attic area which will become the bunk. The rest of the space (the 6' attic was overkill, but it came with the truck, so I will use it) will be lightweight storage for clothing or something else very light. I dont want to overload the attic with weight.

The box itself is 25'. I will be using the last 10' of the truck for a workshop/tool storage area. (it will be a nice change of pace to not have my tools (literally) under my feet) This leaves me with little under 15' for living space, which should be enough considering the bunk is over the cab and not included in the 15'. The back of the truck has a working 1800lb liftgate, which will make loading and unloading rollaways filled with tools *much* easier

First the before pics. The truck itself is about 300 miles away from me atm, so the pics are off the net, sorry for the quality, but you will get the idea of what I am working with at least

The very first question is the decals/vinyl on the outside.. heat gun and goo gone to remove them would be my first choice. Paint will be last but I have read much on the subject so far, and I am wondering why an oil based primer but a latex/acrylic finish?

Onwards to the inside (and the important stuff). I have not seen too many pics of the insulation as it's being installed. I am guessin everyone used either straight rigid board, or lined rigid board. Where did everyone draw the line? I am thinking atm I want a R14 (or thereabouts) so I need a double layer (for a total of 2 inches). But having never done this before, I am wondering will that create chaos when it comes time to install the windows?

More as I think up an intelligent way to present the 1,000,001 questions running around in my head atm.

Attachments

Last edited: