Ran D. St. Clair

Senior Member

- Joined

- Apr 3, 2009

- Messages

- 212

10 pounds of stuff in a 5 pound bag…

The truck may be done, but there is still plenty left to do. I have to move out of my house and into the truck. Some of you may know what it is like to seriously down size your life but the rest will just have to imagine. Tools and basic supplies are my biggest concern. I want to be able to maintain the truck myself, within reason, and I want to keep as many of my smaller hand tools as possible.

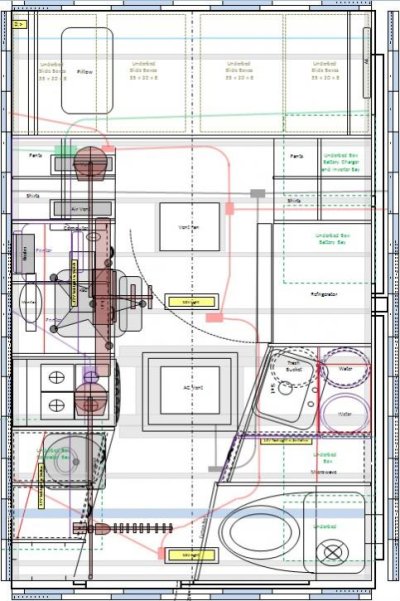

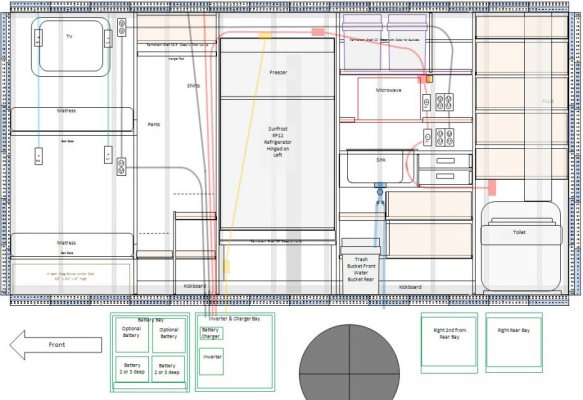

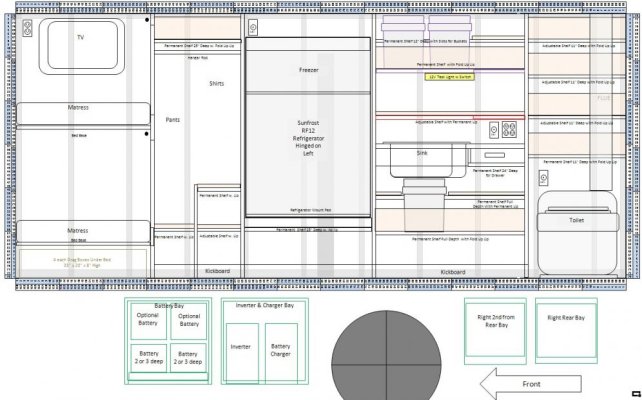

At first I was thinking to load up my Kennedy tool box and then stow it in one of the underbed bays. I tried it, and it worked, but the tool box must have weighed about 80 pounds. It was really hard to get into and out of the bay and I couldn’t access the tools without taking the whole thing out. It also didn’t make very good use of the available space. Eventually I realized that I needed to parcel the tools into smaller containers.

It seems pretty obvious now, but clear plastic totes are a much better solution. I measured my underbed boxes, and then made several trips to my local “Big Lots” discount store. The people in the store probably thought I was nuts, stacking totes in different configurations and measuring the resultant pile. I found a combination of 6 medium totes, plus 4 each 3 drawer units filled the space nicely, plus a large lid on top acts as a removable tray for large flat items.

The 24 plastic drawers are up front and mostly accessible without having to remove anything. I added some EPP (Expanded Polypropylene) packing foam to wedge everything in place and keep it from bouncing around. My two right rear underbed boxes are the same size so they both are loaded with the same combination of totes.

The larger underbed box that contains my inverter and battery charger has some unused space, and 3 somewhat larger totes fit in there nicely. None of these 23 totes weighs much over 25 pounds so I can easily pull them out to get to whatever I need. Since the totes are mostly clear I can often see what I need without having to take everything out. They are made of plastic so they won’t rust, and I figure they will help keep my tools dry when rain water gets past the door seals, which it does a little bit.

Its not as nice as a regular garage where I can spread everything out for immediate access, but it is way better than one big disorganized pile. The good news is that I was able to keep most of my small tools along with a decent assortment of small materials. The bad news is that I was able to keep too much stuff, and I probably should have put more effort into weeding it down to a bare minimum. That can still happen, though these things tend to not happen unless forced.

Some new pictures have been added under keyword “Stealth”.

Meanwhile I still have a ton of stuff to sell, give away, or otherwise get rid of. I plan to put some of the larger and more expensive tools like the welder and the table saw into storage. That stuff is worth a lot of money, at least to me. If I try to sell it I will get pennies on the dollar. If my living situation ever stabilizes it would be a shame to pay full price to replace it all.

All of this is made far more difficult because I don’t know what my Ex-wife is going to do. If she comes after me like I expect she will, then I will need to bug out quickly. If she decides to be reasonable then I have turned my life upside down for nothing. (What am I saying? Her, reasonable? That will never happen…) All heck is going to break loose about mid June. Then we will see…

To a point, all this minimizing and simplifying is a good thing. It gives me options regardless of the reason. Beyond that point it’s just grief and destruction. I don’t see any way to be reasonably prepared without some grief and destruction. I just have to draw the line as best I can and accept the necessary compromises. I may look back on this someday as my declaration of freedom… or the time I went crazy… or stupid… or all of the above…

The truck may be done, but there is still plenty left to do. I have to move out of my house and into the truck. Some of you may know what it is like to seriously down size your life but the rest will just have to imagine. Tools and basic supplies are my biggest concern. I want to be able to maintain the truck myself, within reason, and I want to keep as many of my smaller hand tools as possible.

At first I was thinking to load up my Kennedy tool box and then stow it in one of the underbed bays. I tried it, and it worked, but the tool box must have weighed about 80 pounds. It was really hard to get into and out of the bay and I couldn’t access the tools without taking the whole thing out. It also didn’t make very good use of the available space. Eventually I realized that I needed to parcel the tools into smaller containers.

It seems pretty obvious now, but clear plastic totes are a much better solution. I measured my underbed boxes, and then made several trips to my local “Big Lots” discount store. The people in the store probably thought I was nuts, stacking totes in different configurations and measuring the resultant pile. I found a combination of 6 medium totes, plus 4 each 3 drawer units filled the space nicely, plus a large lid on top acts as a removable tray for large flat items.

The 24 plastic drawers are up front and mostly accessible without having to remove anything. I added some EPP (Expanded Polypropylene) packing foam to wedge everything in place and keep it from bouncing around. My two right rear underbed boxes are the same size so they both are loaded with the same combination of totes.

The larger underbed box that contains my inverter and battery charger has some unused space, and 3 somewhat larger totes fit in there nicely. None of these 23 totes weighs much over 25 pounds so I can easily pull them out to get to whatever I need. Since the totes are mostly clear I can often see what I need without having to take everything out. They are made of plastic so they won’t rust, and I figure they will help keep my tools dry when rain water gets past the door seals, which it does a little bit.

Its not as nice as a regular garage where I can spread everything out for immediate access, but it is way better than one big disorganized pile. The good news is that I was able to keep most of my small tools along with a decent assortment of small materials. The bad news is that I was able to keep too much stuff, and I probably should have put more effort into weeding it down to a bare minimum. That can still happen, though these things tend to not happen unless forced.

Some new pictures have been added under keyword “Stealth”.

Meanwhile I still have a ton of stuff to sell, give away, or otherwise get rid of. I plan to put some of the larger and more expensive tools like the welder and the table saw into storage. That stuff is worth a lot of money, at least to me. If I try to sell it I will get pennies on the dollar. If my living situation ever stabilizes it would be a shame to pay full price to replace it all.

All of this is made far more difficult because I don’t know what my Ex-wife is going to do. If she comes after me like I expect she will, then I will need to bug out quickly. If she decides to be reasonable then I have turned my life upside down for nothing. (What am I saying? Her, reasonable? That will never happen…) All heck is going to break loose about mid June. Then we will see…

To a point, all this minimizing and simplifying is a good thing. It gives me options regardless of the reason. Beyond that point it’s just grief and destruction. I don’t see any way to be reasonably prepared without some grief and destruction. I just have to draw the line as best I can and accept the necessary compromises. I may look back on this someday as my declaration of freedom… or the time I went crazy… or stupid… or all of the above…