Hi all.

I have been checking out this site for a while now and I figured I'd post up my project now that I have actually started.

I am involved in a offroad race sport called ultra4 racing where I race a rock crawler. For the past 3 years I have been hauling my rig all over the country with a pickup and an enclosed trailer. It is not really any fun to drive and not the safest thing on the road for sure.

I finally pulled the trigger on a 1999 Kenworth t-300 expedite truck with a 24' box and 6' sleeper. It has 550k miles on it. I had been watching the truck for months on craigslist and the owner of the truck dropped his price to $10k I finally went to look at the truck. As it turns out the truck is in great shape. It has had an in chassis rebuild on the the engine (cumins isc) a new turbo fan clutch radiator batteries and front runners.

the only issue I have found with the truck is that the boot between the sleeper and cab was bad. It was a pretty easy fix and the cab is now dry.

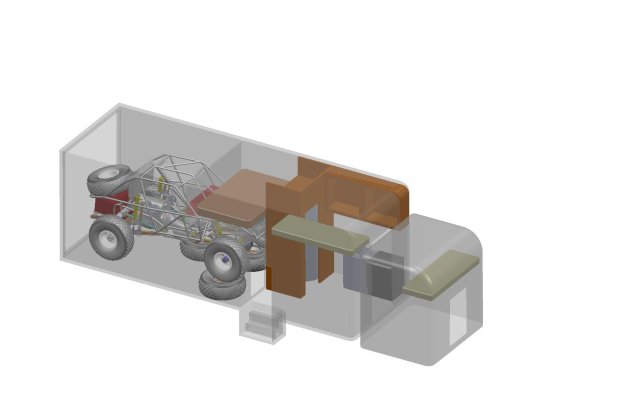

My plan is to build out the front 8' of box to be a camper and the rest will be garage for my race rig.

The first thing I figured I would work on is aquiring parts. One stop to the local rv dealer and I was able to get a 30' fifth wheel camper with roof damage for a few hundred dollars. It had some good parts inclduding windows doors A/C heat awning. I also had an old truck camper which had a ton of good parts as well which stripped for parts as well.

Right now I am trying to figure out a layout that works both for racing and camping with my faimily. I attached a screen shot from solidworks of what I have been playing around with (I am an engineer by day) For sure I will make a pass through from the sleeper to the box and do some type of seating in the sleeper that can fold out into a bed as well. I figure I can use the under body on one side for tanks and the other side for race related storage.

I am interested in any input I can get.

I have been checking out this site for a while now and I figured I'd post up my project now that I have actually started.

I am involved in a offroad race sport called ultra4 racing where I race a rock crawler. For the past 3 years I have been hauling my rig all over the country with a pickup and an enclosed trailer. It is not really any fun to drive and not the safest thing on the road for sure.

I finally pulled the trigger on a 1999 Kenworth t-300 expedite truck with a 24' box and 6' sleeper. It has 550k miles on it. I had been watching the truck for months on craigslist and the owner of the truck dropped his price to $10k I finally went to look at the truck. As it turns out the truck is in great shape. It has had an in chassis rebuild on the the engine (cumins isc) a new turbo fan clutch radiator batteries and front runners.

the only issue I have found with the truck is that the boot between the sleeper and cab was bad. It was a pretty easy fix and the cab is now dry.

My plan is to build out the front 8' of box to be a camper and the rest will be garage for my race rig.

The first thing I figured I would work on is aquiring parts. One stop to the local rv dealer and I was able to get a 30' fifth wheel camper with roof damage for a few hundred dollars. It had some good parts inclduding windows doors A/C heat awning. I also had an old truck camper which had a ton of good parts as well which stripped for parts as well.

Right now I am trying to figure out a layout that works both for racing and camping with my faimily. I attached a screen shot from solidworks of what I have been playing around with (I am an engineer by day) For sure I will make a pass through from the sleeper to the box and do some type of seating in the sleeper that can fold out into a bed as well. I figure I can use the under body on one side for tanks and the other side for race related storage.

I am interested in any input I can get.