Kenn-TC

Senior Member

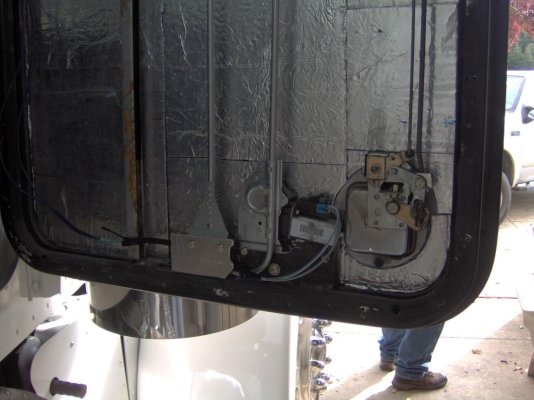

door magnets

Thanks for the kind words. I installed the stronger (stacked magnets) and they hold much better. I will be going to an RV outing next week and should be able to test them.

Thanks for the kind words. I installed the stronger (stacked magnets) and they hold much better. I will be going to an RV outing next week and should be able to test them.