Kenn-TC

Senior Member

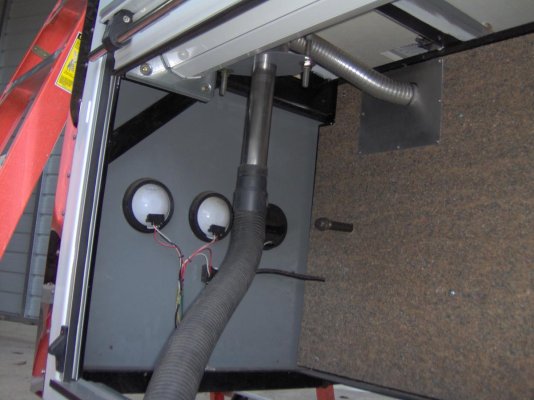

more vents

andyg I have cut the vent holes in the outside skin. In the earlier pictures you can see them. I think they are about 23 x 13 and I covered them with cardboard boxes in an attempt to keep the outside cold air out. In Oregon we have been below freezing for almost a week with 4" of snow on Friday. My electric heater keeps the inside about 20 to 30 degrees above the outside temp. More snow for tomorrow night.

andyg I have cut the vent holes in the outside skin. In the earlier pictures you can see them. I think they are about 23 x 13 and I covered them with cardboard boxes in an attempt to keep the outside cold air out. In Oregon we have been below freezing for almost a week with 4" of snow on Friday. My electric heater keeps the inside about 20 to 30 degrees above the outside temp. More snow for tomorrow night.