|

|

09-08-2011, 04:30 PM

09-08-2011, 04:30 PM

|

#1

|

|

Junior Member

Join Date: Sep 2011

Location: NE Kansas

Posts: 5

|

In the design stages

In the design stages

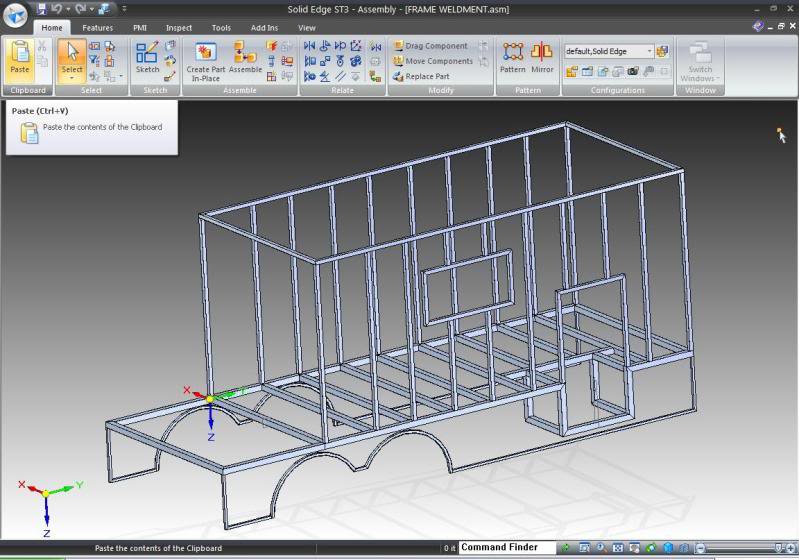

I am just working on starting the design of my toterhome conversion. I started modeling my framework up so i can keep an eye on what it is going to weigh. I will be putting at least one slideout in it, so i am hoping i can get a solid model from the mfg to put it into my model. The box will be going on a 87 Freighliner FLD-120. I will post up some pictures of the truck when i get a chance. This will be my first project of this size, the framework so far is 3" Sq. .120" wall thickness for the floor frame, and 2"sq for the wall and ceiling. I am open for suggestions or things to watch out for on this project. Like i said i am just getting started designing.

|

|

|

09-08-2011, 07:38 PM

09-08-2011, 07:38 PM

|

#2

|

|

Junior Member

Join Date: Aug 2011

Posts: 4

|

I am getting ready to do the same project. Were did you get your design program from?

__________________

|

|

|

09-09-2011, 02:57 AM

09-09-2011, 02:57 AM

|

#3

|

|

Junior Member

Join Date: Sep 2011

Posts: 5

|

What are your measurements ?

|

|

|

09-09-2011, 08:18 AM

09-09-2011, 08:18 AM

|

#4

|

|

Junior Member

Join Date: Sep 2011

Location: NE Kansas

Posts: 5

|

I am a mechanical design engineer by trade, so the software is what i use at work. It is Solid Edge, and is very pricey.

The box is 18 feet long, 102" wide, 91" Inside height.

I will be using the truck to pull a 36' Fifth Wheel car trailer pulling a dirt modified racecar.

|

|

|

09-09-2011, 05:19 PM

09-09-2011, 05:19 PM

|

#5

|

|

Junior Member

Join Date: Aug 2011

Posts: 4

|

Can you keep posting your design pictures. that would help me alot with my box build and what materials you are using for the frame.

|

|

|

09-09-2011, 05:38 PM

09-09-2011, 05:38 PM

|

#6

|

|

Senior Member

Join Date: Jan 2011

Posts: 527

|

Great looking design from your program. I am jealous.

The 3x3 is probably overkill for your floor, 2x3 would be just as strong positioned correctly and a lot lighter. The .120 wall could probably be lighter gauge as well. Certainly the wall could be much lighter gauge. It is real easy to go overboard on strength (objectively not a bad thing) but weight is critical, both for fuel mileage, and for not overloading the front axle, which is real easy to do. You be amazed at what plywood, wall board, aluminum and even fabric and carpet add up to in a unit that size. Your twin screw truck won't be nearly as bad as my single, at least your front rear can take some of the box weight. Also keep that in mind when positioning fresh/gray/black tanks as to keeping weight to the rear.

Good luck! Dave

|

|

|

09-09-2011, 11:03 PM

09-09-2011, 11:03 PM

|

#7

|

|

Senior Member

Join Date: Apr 2007

Location: Camano Island, WA

Posts: 163

|

For those on a budget you can do quite a lot with Google Sketchup, allows for full 3D modeling and some rendering. There is a great online collection of materials, componants, and even some 3d truck models. Best part is the basic version is available by download for free. I am just starting the design of my future truck conversion and will be using a combination of Sketchup and Autocad software I use for my business. Makes it nice to be able to walk thru your model before actually start cutting steel. When you have a design you like, may not be a bad idea to run it by a structural engineer to see where you might save some weight, and or need to beef up a bit. For those home builders a few bucks spent at an engineer may well save a lot more down the road.

Dave

|

|

|

09-17-2011, 11:02 PM

09-17-2011, 11:02 PM

|

#8

|

|

Senior Member

Join Date: Mar 2008

Location: West Fargo ND

Posts: 300

|

Guys be very careful, you have to plan every thing out, it is super SUPER easy to overload that front axle. Your Over-the-road-highway truck was designed for a 40K trailer with 15-20k on the pin, now you have next to nothing on the pin, and now all the entire weight of that box WILL BE equally spread like 50/50 on the front and rear axles.

Think about that original design, for optimal highway operation, load capacity, truck ride, and of course fleet cost, The spec as light of a front axle to save overall weight and ride comfort for the truck, as most of the time they need all the capacity they can on the drivers.

To overcome this problem, most coach builders will hang a bunch of the box rear of the rear axle to leverage the weight off the steer axle like a huge teeter totter, using the center of the drives as the pivot. An extreme example of this is a front engine'd Class A or Van based Class C, they all have those real long tails to pivot the pounds off the steer axle. (its also why you may never see a diesel E450 based Class C as the engine itself is too heavy once even a lightweight stick and aluminum RV body is loaded on it.)

When a Truck conversion involves streching the wheelbase front axle weight adds up even quicker (as mine did.)

The design, shown in the OP looks to be a toterhome box. Those balance ONLY with the fiver hooked to the back of the truck. Try to run bobtail to take 8 buds to tailgate at the football game, and that front axle is way past ugly.

I search racing junk once a week, I cringe at what my 80K might buy now as a finished RV with this economy. I also cringe at those long stretched trucks and wonder how big of water tanks the must have just to pivot the weight off the front axles. There is no doubt some very over weight trucks out there and its just a matter of time before some LEO starts scaling us.

Even if you think you may never get scaled, some day you will want to sell your $50-100K investment, you will have to disclose somewhere in that transaction that the front axle is over its limit.

I'll try to follow this thread a bit closer, good luck with your projects guys!

-blizzND

__________________

2001 GMC 6500 Topkick, 22' box, dropped frame, designed to fit into a 9' garage door. 3126 CAT 6spd Man Lo-Pro 19.5's w/ 3.07 rear axle ratio

|

|

|

09-18-2011, 08:51 PM

09-18-2011, 08:51 PM

|

#9

|

|

Senior Member

Join Date: Feb 2009

Location: St. Paul, MN

Posts: 1,819

|

blizzND is a pretty smart guy. And he's got lots of experience to speak from.

__________________

'03 Freightliner FL112, 295" wheel base, with '03 United Specialties 26' living quarters, single screw, Cat C12 430 h/p 1650 torque, Eaton 10speed , 3.42 rear axle ratio

|

|

|

09-18-2011, 10:33 PM

09-18-2011, 10:33 PM

|

#10

|

|

Senior Member

Join Date: Nov 2010

Location: Grafton

Posts: 285

|

This discussion of weight location, front axle capacity, rear axle weight, overhang, etc. reminds of getting my pilots license 40 years ago.

We were taught to do weight and balance calculations be essentionally measuring the weight of something (fuel, oil, front seat passenger, rear seat passenger, baggage, etc.) and its location in the plane as a distance from a known point (datum); knowing the center of gravity of the empty plane, and then calculating the loaded CG. Couldn't something similar be done with these truck builds? Using Excel it would seem to be to be easy. Start out by weighing the empty chassis, establish a starting CG, and go from there.

Anyone have thoughts?

__________________

Started looking for 379 Peterbilt TC, 24' to 30' box, bumper pull--but ended up w/1999 Liberty Coach conversion of 45' Prevost XLV bus. 1,000sf heated/AC'd race shop w/dump station, 50amp shore pwr where bus parks, 3 NASCAR/ARCA race cars & 26' Bravo trailer.

|

|

|

09-19-2011, 10:27 PM

09-19-2011, 10:27 PM

|

#11

|

|

Senior Member

Join Date: Mar 2008

Location: West Fargo ND

Posts: 300

|

thats pretty much what I did, I tried to keep it simple,

I weighed my truck very carefully at the truck scales

I calculated every thing on the 16" centers because thats where my bed crossmembers, the vertical posts, and the roof rafter tubes were located. Then I spit the weight of each sheet of flooring, roofing and wall materials to the nearest 16" point.

You do the same with everything, from the weight of the Microwave, generator, cabinets, inverter and everything else I loaded into my conversion. Long things like a/c and water tanks get divided up into 2-3 datum points.

I used a dial hunting scale to weigh some things, others I held while on a floor scale. some materials can be found in the machinist handbook.

The stuff adds up, even the vinyl for the padded walls, weighed like 60 lbs.

Then its all a function of distance from the front axle x weight, just like your airplane balance.

then you subtract the distance from rear axle, just like High School physics, lever arm rotation equations.

I came out really close. to start with...

once I could drive my truck after the stretch, I weighed it again. pretty close...

After my box was built, I weighed it again, I was surprised to see my figures off a bit, so I had to re-figure to get close after factoring changes the box builder made to my design.

Even after all that I'm way heavier on my steering then I would like, but my truck had only a 7000lb front axle so it was close before I started and the stretch just made things that much harder.

Do to the unique design of my rear bedroom adding more behind the rear axle really wouldn't do much on my interior and would just add to my overall length. I wish I could have added 2-3 more feet for leveraging that front axle.

I'll have to re-upload my charts and drawings to another hosting site...

if your are into reading poor grammar and word structure here is the link to my build...

http://www.rvnetwork.com/index.php?showtopic=73051

blizz

__________________

2001 GMC 6500 Topkick, 22' box, dropped frame, designed to fit into a 9' garage door. 3126 CAT 6spd Man Lo-Pro 19.5's w/ 3.07 rear axle ratio

|

|

|

09-19-2011, 11:12 PM

09-19-2011, 11:12 PM

|

#12

|

|

Senior Member

Join Date: Nov 2010

Location: Grafton

Posts: 285

|

That is pretty much the same way I'd do it. if the weights are right and the measurement right, you should be right on.

I've seen some of the bumper pull trucks with lots of truck behind the rear axles and now I'm realizing that is done to get weight off the front axle.

Keep up the good work.

Dick

__________________

Started looking for 379 Peterbilt TC, 24' to 30' box, bumper pull--but ended up w/1999 Liberty Coach conversion of 45' Prevost XLV bus. 1,000sf heated/AC'd race shop w/dump station, 50amp shore pwr where bus parks, 3 NASCAR/ARCA race cars & 26' Bravo trailer.

|

|

|

09-20-2011, 09:55 AM

09-20-2011, 09:55 AM

|

#13

|

|

Junior Member

Join Date: Sep 2011

Location: NE Kansas

Posts: 5

|

Thanks for the input guys, my king pin will be at the rear most point on the deck behind the toter home box. The trailer i am pulling weighs somewhere in the range of 17,000 and is pretty heavy on the king pin. The twin screw axle locations are not set in stone at this point. I know this is not good logic from an engineering standpoint, but out here in rural kansas guys convert regular over the road tractors to grain hauling trucks with 20' boxes on the rear, hauling 600 bushels of corn * 60 lbs/bu = 36,000lbs + the weight of the bed, with virtually nothing hanging over the rear axles. To my knowledge the front axles are not being upgraded in these trucks??

|

|

|

09-20-2011, 11:06 AM

09-20-2011, 11:06 AM

|

#14

|

|

Member

Join Date: Oct 2009

Posts: 47

|

When I was talking with the rep from Renegade the other day at the RV show, he mentioned that If I wanted to supply my own chassis for a conversion, to factor in a few thousand $ to stretch the frame, and a few thousand $ for a 16k front axle. It appears they MFG's are paying more attention to this..

Personally, if able to spec it myself and cost wasn't a factor, on my sketched-up 40' OAL conversion, I'd like a single screw with a retractable tag axle for when I'm towing heavy or up when bobtailing it for best MPG, but that's a lot of work for a minor reward.

__________________

-Currently window-shopping for a class8 coach conversion...

|

|

|

09-20-2011, 03:00 PM

09-20-2011, 03:00 PM

|

#15

|

|

Senior Member

Join Date: Feb 2009

Location: St. Paul, MN

Posts: 1,819

|

So here's a question kind of on topic. My truck has a 12k front axle. I scaled it with full fuel and empty water, myself and my son in the front seats. Front axle weighed 12, 060 lbs. Now, I have 200 gallon fresh water tanks and they are completely behind the rear axle line (single rear axle). So, if I filled those with water it might lighten the weight on the front just a few pounds?

Also, I saw a truck/tractor that looked identical to mine but had a much heavier front axle by the looks of the front tires. I located a 16k front axle that looks like it might bolt onto my truck. Is that all it would take, including larger tires for a heavier load rating? Or is there more to it? Think it would improve the ride up front or make it worse? I know the Columbia's have an air ride front axle, I wonder if those are interchangeable with the FL112 frames? Mine is steel springs up front. Maybe I should pay a visit to a truck spring suspension shop and pick the guys brains too?

__________________

'03 Freightliner FL112, 295" wheel base, with '03 United Specialties 26' living quarters, single screw, Cat C12 430 h/p 1650 torque, Eaton 10speed , 3.42 rear axle ratio

|

|

|

09-20-2011, 09:24 PM

09-20-2011, 09:24 PM

|

#16

|

|

Senior Member

Join Date: Jul 2011

Location: Tomball

Posts: 1,414

|

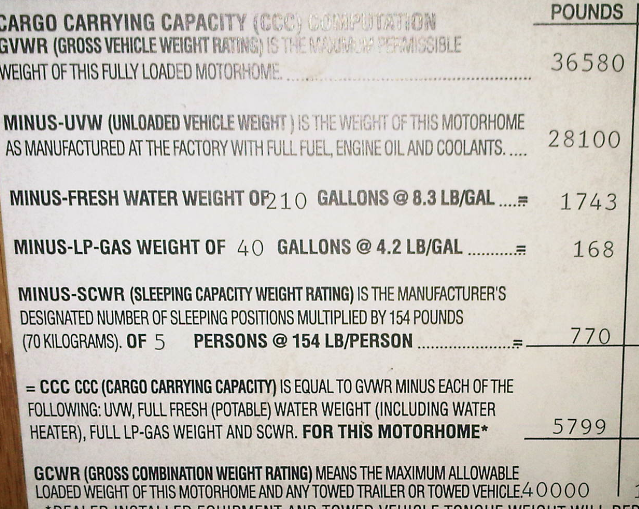

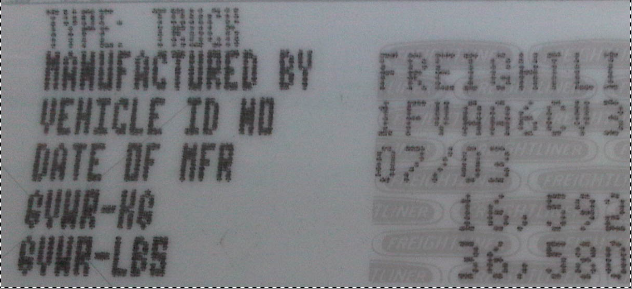

subscribed / following - just checked the door tag on our columbia chassis.

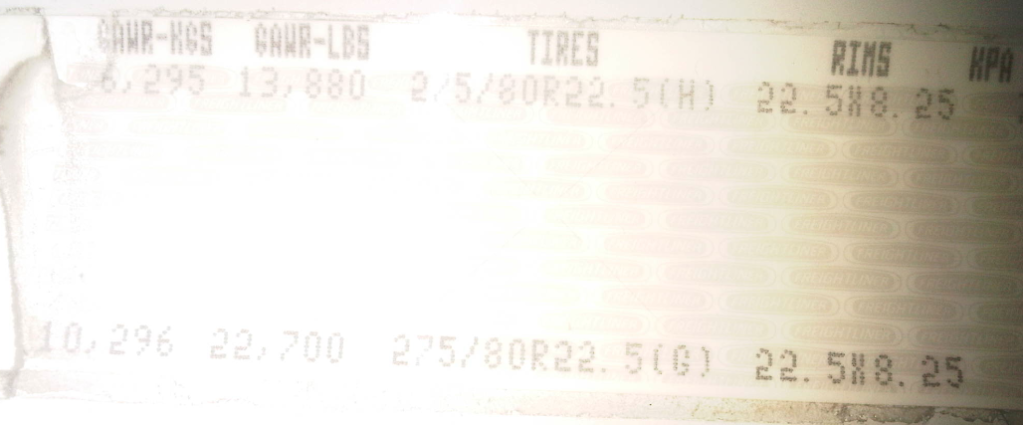

front axle is 17,880 the rear is 22,700 !

ill be weighing mine this week - ive weighed it before but the scale i used wasnt multi-axle, i know fairly well loaded i was right at 30k (where my gvwr is 36580 & my gcwr is 40k)

__________________

Don R.

'04 Haulmark (M42386) 42', 2 slide, 10kw - Pictures

'04 F350 CrewCab Longbed 4x4, 50g aux tank & gear vendors dbl over

|

|

|

09-21-2011, 11:43 AM

09-21-2011, 11:43 AM

|

#17

|

|

Member

Join Date: Oct 2009

Posts: 47

|

Quote:

Originally Posted by Bob86ZZ4

So here's a question kind of on topic. My truck has a 12k front axle. I scaled it with full fuel and empty water, myself and my son in the front seats. Front axle weighed 12, 060 lbs. Now, I have 200 gallon fresh water tanks and they are completely behind the rear axle line (single rear axle). So, if I filled those with water it might lighten the weight on the front just a few pounds?

|

I'd bet ya it wouldn't take much water to get you under your 12k limit, since any weight behind the axle will help lever weight off the front. just guesstimating, (it could be calculated if needed), but I'd bet 50 gallons of water would get you under.

Quote:

Originally Posted by Bob86ZZ4

Also, I saw a truck/tractor that looked identical to mine but had a much heavier front axle by the looks of the front tires. I located a 16k front axle that looks like it might bolt onto my truck. Is that all it would take, including larger tires for a heavier load rating? Or is there more to it? Think it would improve the ride up front or make it worse?

|

This I can't say for certain, but I'd bet a 16k front axle truck would have 16k springs, as well, be they air or leaf. This would seem to make the ride harsher, but if you go from a 12k leaf to 16k air, hmmmm.

__________________

-Currently window-shopping for a class8 coach conversion...

|

|

|

09-21-2011, 12:34 PM

09-21-2011, 12:34 PM

|

#18

|

|

Senior Member

Join Date: Feb 2009

Location: St. Paul, MN

Posts: 1,819

|

Quote:

Originally Posted by bushpilot

subscribed / following - just checked the door tag on our columbia chassis.

front axle is 17,880 the rear is 22,700 !

ill be weighing mine this week - ive weighed it before but the scale i used wasnt multi-axle, i know fairly well loaded i was right at 30k (where my gvwr is 36580 & my gcwr is 40k)

|

Wow, that's great you've got a 17,880 front axle. I've got the same rear axle as you. I'm kind of confused though. Wouldn't your gvwr be 40k with those two axles added together? And isn't the gcwr closer to 80k? Does gcwr = gross combined weight rating, meaning combination of veh. and any trailer? I thought gvwr is gross veh. weight rating, which is the maximum amount the manufacturer says can be on the single veh. itself?

Is your 17,880 front axle an air ride or steel springs?

__________________

'03 Freightliner FL112, 295" wheel base, with '03 United Specialties 26' living quarters, single screw, Cat C12 430 h/p 1650 torque, Eaton 10speed , 3.42 rear axle ratio

|

|

|

09-21-2011, 01:11 PM

09-21-2011, 01:11 PM

|

#19

|

|

Senior Member

Join Date: Jul 2011

Location: Tomball

Posts: 1,414

|

Quote:

Originally Posted by Bob86ZZ4

Wow, that's great you've got a 17,880 front axle. I've got the same rear axle as you. I'm kind of confused though. Wouldn't your gvwr be 40k with those two axles added together? And isn't the gcwr closer to 80k? Does gcwr = gross combined weight rating, meaning combination of veh. and any trailer? I thought gvwr is gross veh. weight rating, which is the maximum amount the manufacturer says can be on the single veh. itself?

Is your 17,880 front axle an air ride or steel springs?

|

good ol' fashion leafs up front

Oh CRAP - i made a typo last night ! the Front is 13880, not 17880

so the GVWR (13880+22700) is 36580 (which i think i said before)

im going by what the drivers door tag & the tag inside the kitchen cabinet says combined (loaded coach and trailer) is 40k.

i WISH i was 80k rated (im single screw-ed) - ive got no plans to pull a stacker <mental note: play the lotto>....but if im not careful i could be OVER weight - pulling a simple little jeep (ill just leave that topic alone).

__________________

Don R.

'04 Haulmark (M42386) 42', 2 slide, 10kw - Pictures

'04 F350 CrewCab Longbed 4x4, 50g aux tank & gear vendors dbl over

|

|

|

09-21-2011, 03:51 PM

09-21-2011, 03:51 PM

|

#20

|

|

Senior Member

Join Date: Feb 2009

Location: St. Paul, MN

Posts: 1,819

|

Don, that can't possibly be correct. I think somebody made a mistake there. A 5k lb. max trailer?! No way. I think what they meant was a 40k lb. trailer. Your engine and trans are certainly made for an 80k lb load, all day every day. I think somebody at Showhauler mixed things up. Is there a gcwr rating on the original Freightliner sticker?

__________________

__________________

'03 Freightliner FL112, 295" wheel base, with '03 United Specialties 26' living quarters, single screw, Cat C12 430 h/p 1650 torque, Eaton 10speed , 3.42 rear axle ratio

|

|

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

» Recent Threads

» Recent Threads |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|